Lenovo yesterday announced the Europe based Innovation Centre specializing in HPC and AI, will now operate with enhanced customer experience from the in-house manufacturing facility in Budapest.

Running the new Innovation Centre operations from the Budapest factory with onsite inventory stock, allows Lenovo customers to access the most advanced power and cooling infrastructure solutions and latest generation technology within the supply chain. This access ensures that workloads are tested on accurate representations of end purchased solutions, enabling customers to know with certainty the Lenovo solution installed will perform successfully for the intended workload.

The location of Lenovo’s new Innovation Centre will provide:

- Increased capacity to host up to 50% more customer POC’s a year

- Access to the latest technology for customer POC’s to be built with significantly reduced lead time

- On site facilities for potential and existing customers to see live testing of POC’s and the manufacturing of their final solutions in house

- Lenovo’s first liquid cooling testing and demonstration facility within Europe

Per Overgaard, CTO, Infrastructure Solutions Group EMEA said “Lenovo leads with a clear commitment to our customers throughout their buying journey. This Innovation Centre facilitates a collaborative approach to infrastructure solution building, and now our customers can test their workloads more accurately, on the latest technology, and ensure their solution is precisely the configuration required.”

Innovation Centre Value and Output

Lenovo Innovation Centers allow potential customers to pilot new data centre solutions in real-time before making a purchase. The new facility provides the opportunity for customers to test joint solutions built with partners including Intel, AMD, and NVIDIA.

Virtual, and now in person, access to POC’s allows customers to test workloads in datacentre environments with full transparency, and the ability to adjust configurations that deliver better value.

Lenovo’s European customers benefit from knowing that the datacentre infrastructure tested in the Innovation Centre, and shipped from Budapest come from a secure and stable supply chain, and contribute to the European economy.

Sustainability

Customers are prioritizing sustainability throughout their buying journey, and Lenovo’s commitment to reach net-zero greenhouse gas emissions by FY2049/50 all operations on site in our manufacturing facilities.

Manufacturing in region eliminates the need for customers to incur long-distance shipping charges and wait times, but the shorter shipping distances also mean the CO2 emissions generated are also reduced.

The European manufacturing facility itself was built from the ground up with sustainability in mind, and since opening has increased the building heating isolation, completed installation of a lighting sensor systems, and optimized air compressor waste heat utilization. The second phase of solar panel installation is now underway and will enable more operations to be run with a reduced impact on the environment in the future.

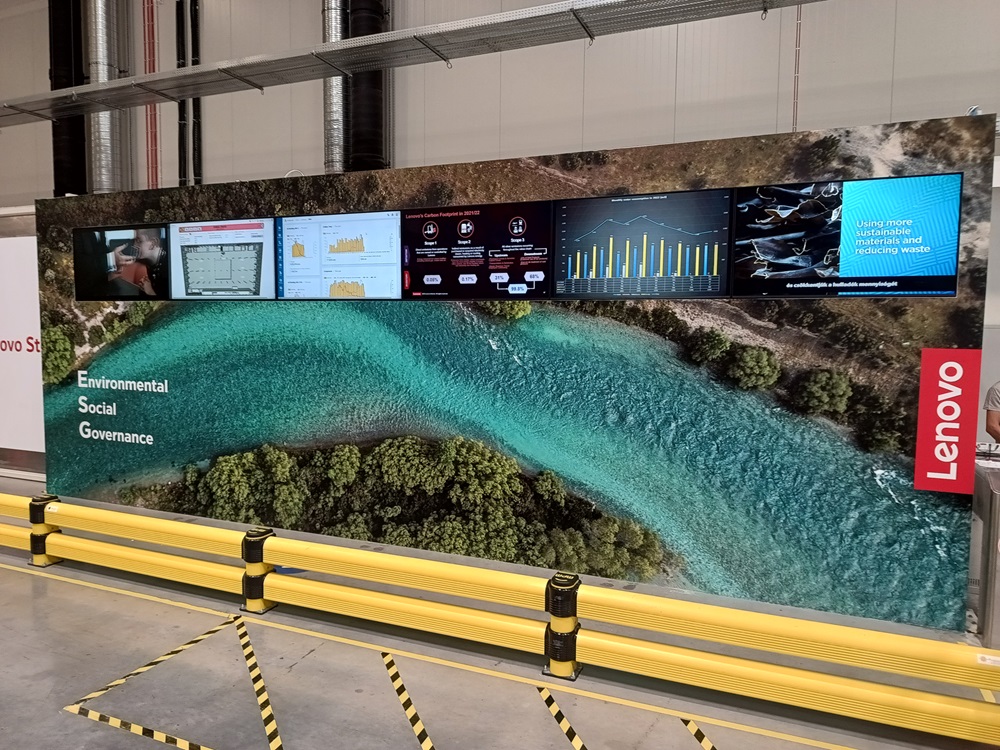

Onsite, customers testing POC’s in the Innovation Centre will also be able to see the real time energy and water consumption data across the facility on the newly unveiled Environmental, Social and Governance wall (pictured below).

Szabolcs Zolyomi, Factory Site Leader at Lenovo, commented “Over 200 existing and prospective customers have visited our facilities in Budapest since opening just over a year ago, and now with the addition of the new Innovation Centre we look forward to welcoming many more from the testing phase to the manufacturing process. We engage with our customers on a human level and know they care about where their infrastructure comes from, how it’s made, and the impact each test, purchase, and shipment have on the environment. We are focused on enabling deeper collaboration, transparency and understanding between Lenovo and our customers, and now we can offer the benefits from our ongoing sustainability efforts on site too.”

Article Provided